Taw qhia

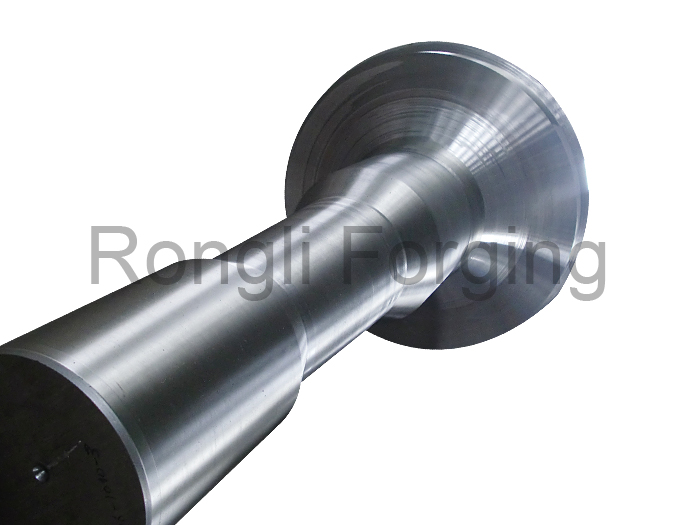

Rongli Forging Co., Limited muaj peev xwm muab forged & machined ncej mus txog 20 meters (66 ko taw) ntev thiab 70 tons (44,000 lbs.) hauv qhov hnyav.Ntau hom khoom siv rau cov qauv sib txawv yog nyob rau hauv kev xyaum ntawm no hauv peb lub khw niaj hnub.Peb cov shafts hais lus tau raug xa tawm mus rau North America, Europe, Australia, South Africa, hauv kev lag luam ntawm Shipbuilding, cua zog tsim, mine & hlau ua, hnyav kev lag luam machinery, metallurgy, thiab lwm yam.

Khoom siv

| Txuj | |||||

| North America | Lub teb chaws Yelemees | Tebchaws Askiv | ISO | EN | Tuam Tshoj |

| AISI/SAE | DIN | BS | GB | ||

| 304 | X5CrNi18-10 | 30 4s15 | X5CrNi18-10 | X5CrNi18-10 | 0c19n 9 |

| 316 | X5CrNiMo17-12-2 | 316 S 16 | X5CrNiMo17-12-2 | X5CrNiMo17-12-2 | 0Cr17Ni12Mo2 |

| X5CrNiMo17-13-3 | 316 S 31 | X5CrNiMo17-13-3 | X5CrNiMo17-13-3 | X5CrNiMo17-13-3 | |

| 1020 | C22 E | C22 E | 20 | ||

| 1035 ib | C35 E | C35 E | C35E4 | 35 | |

| 1040 | C40 E | C40 E | C40E4 | 40 | |

| 1045 ib | C45 E | C45 E | C45E4 | 45 | |

| 4 130 | 30 CrMoA | ||||

| 4 140 | 42CrMo4 | 708m4 0 | 42CrMo4 | 42CrMo4 | 42CrMo |

| ib 4330 | 30CrNiMo | ||||

| ib 4340 | 36 CrNiMo4 | 816m4 0 | 40CrNiMo | ||

| 50B | E355 C | S355 JR | q345 ua | ||

| ib 4317 | 17 CrNiMo6 | 820a16 ua | 18 CrNiMo7 | 18CrNiMo7-6 | 17Cr2Ni2Mo |

| 17 CrNiMo7 | |||||

| 30 CrNiMo8 | 823m3 0 | 30 CrNiMo8 | 30 CrNiMo8 | 30Cr2Ni2Mo | |

| 34 NPO 6 | 817m4 0 | 34 NPO 6 | 36CrNiMo6 | 34CrNiMo | |

| Lwm yam khoom siv qib raws li tus neeg siv khoom xav tau | |||||

Forging method: Qhib tuag forging / dawb forging

1. Khoom siv: Carbon steel, alloy steel, stainless hlau

2. Khoom siv: DIN / ASTM / AISI / ASME / BS / EN / JIS / ISO

3. Cov khoom siv tshuab: Raws li cov neeg siv khoom xav tau lossis tus qauv.

4. Nyhav: Txog 70 Tons ntawm forging tiav.90 Tons rau ingot

5. Ntev: Txog li 20 meters rau forging

6. Kev xa khoom: Kub kho thiab ntxhib machined

7. Kev lag luam: Shipbuilding, tsim hluav taws xob, mine & hlau ua, hnyav kev lag luam machinery, metallurgy, thiab lwm yam.

8. Kev tshuaj xyuas: Tshuaj ntsuam xyuas nrog spectrometer, Tensile test, Charpy test, Hardness Test, Metallurgy test, Ultrasonic test, Magnetic Particle test, Liquid Penetration test, Hydro test, Radiographic test yog siv tau.

9. Kev lees paub zoo: Raws li ISO9001-2008